Applied Research and Development of a Three-Dimensional Topography System for Firearm Identification using GelSight

Ryan Lilien

Abstract

The proposed work is to investigate and develop a novel, accurate, and low-cost system for structural 3D imaging and comparison of cartridge casings and to demonstrate the system's potential for increasing the quality and reducing the cost of forensic analyses. Despite the importance of tool mark analysis in the forensic sciences, the imaging and comparison of tool marks remains a difficult and time consuming endeavor. Cartridge case comparison is based on the observation that microscopic firearm imperfections (such as those on a breech-face) can be transferred to a fired cartridge case. Therefore, two cases with highly similar breech-face impressions are likely to have been fired through the same firearm. The ability to certify two cases as highly similar is therefore a function of both the ability to capture a high-resolution measurement of each case and the ability to identify and match relevant structural features.

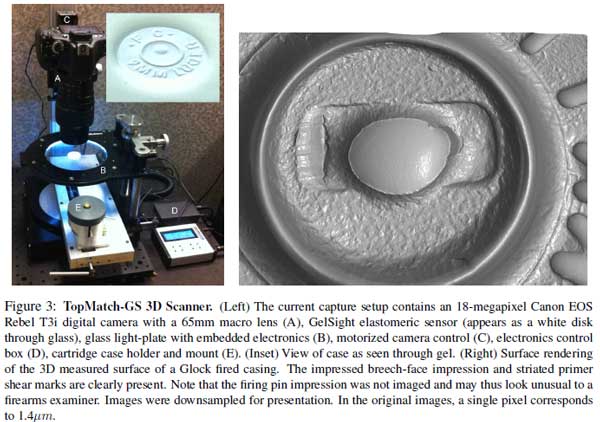

The next generation of methods for the forensic analysis of tool marks should improve accuracy, reduce acquisition and operational costs, and shorten analysis time. Our platform utilizes the recently developed GelSight surface topography imaging system and custom feature-based image comparison software. Compared to competing technologies, our 3D GelSight-based system is fast, inexpensive, and not sensitive to the optical properties of the material being measured. In collaboration with forensics experts, we proposed to improve our hardware and software, conduct several moderate scale experimental benchmarks, and deploy system prototypes. These are critical steps towards the development of a low-cost, fast, and accurate next generation system for cartridge case comparison and database search.

Through this award we completed several important goals. We completed the research and design process and advanced our prototype scanner and casing analysis algorithms to the level where they can now be used in larger research studies and can be deployed to collaborating labs. We demonstrated that our GelSight-based imaging system is able to capture the three-dimensional surface topographies of cartridge cases at high resolution. We tested our imaging and analysis system using several experimental datasets. The results demonstrate the system's current performance on real-world casings (including well and poorly marked casings). We achieve excellent performance on good marking casings and surprisingly good performance on extremely challenging casings, casings that a firearms expert claims would be difficult and time consuming to match. Most importantly, there are no false-positives across approximately 200,000 comparisons. We also evaluated our system using a test set of clean, well marked test fires. We achieve even better performance with these clean casings.

In summary, we have redesigned the base scanner, designed and machined a fully functional cartridge case mount, achieved excellent performance across three experimental datasets, created software which allows 3D visualization of cartridge casings and database search, deployed our hardware and software system to several forensics labs, and we assembled a large experimental set of test fires. These results all strongly support the goals of the proposed study. We have demonstrated a novel technique for the imaging and analysis of cartridge casings and we have shown excellent performance compared to the state-of-the-art alternatives.